Mutf_In: Tata_Mult_Asse_1wo0drd

The concept of multi-tasking in manufacturing has evolved significantly, particularly within Tata’s innovative assembly processes. By integrating advanced technologies and optimizing workflows, Tata demonstrates notable enhancements in productivity and efficiency. This strategic focus not only cultivates a dynamic workforce but also prompts continuous improvement. The implications of such practices extend beyond Tata, suggesting a potential shift in industry standards. What remains to be seen is how these developments will influence future operational paradigms.

The Evolution of Multi-Tasking in Industry

As industries evolved, the concept of multi-tasking emerged as a vital strategy for enhancing productivity and efficiency.

Historical perspectives reveal that its benefits include streamlined operations and increased workforce adaptability. By enabling workers to engage in various tasks simultaneously, organizations harnessed greater output, fostering an environment conducive to innovation and flexibility.

This strategic approach ultimately reshaped industrial practices, paving the way for modern productivity paradigms.

Tata’s Innovative Assembly Processes

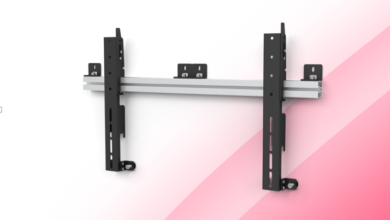

Tata’s innovative assembly processes exemplify the practical application of multi-tasking strategies in manufacturing.

By leveraging Tata technologies, the company achieves significant assembly innovation and process optimization.

These advancements not only enhance productivity but also foster workforce adaptability, allowing employees to efficiently navigate complex tasks.

This strategic approach positions Tata as a leader in the industry, driving continuous improvement and operational excellence.

Impact on Efficiency and Performance

Efficiency and performance in manufacturing are significantly influenced by the innovative assembly processes implemented by Tata.

By establishing robust performance metrics and striving to meet stringent efficiency benchmarks, Tata enhances productivity and reduces waste.

This analytical approach not only drives operational success but also fosters a culture of continuous improvement, enabling the organization to adapt swiftly to market demands while ensuring high-quality outputs.

Future Implications for Workflows and Industries

While the manufacturing landscape continues to evolve, the adoption of advanced assembly processes by leading firms like Tata is poised to reshape workflows and redefine industry standards.

Automation trends will necessitate significant workforce adaptation, compelling industries to retrain employees and reconfigure roles. This shift not only enhances operational efficiency but also empowers workers to engage creatively, fostering an environment ripe for innovation and progress.

Conclusion

In conclusion, Tata’s pioneering approach to multi-tasking in assembly processes not only redefines operational efficiency but also sets a compelling precedent for the entire industry. Like a well-oiled machine, the integration of advanced technologies and adaptive workflows creates a harmonious balance that fuels innovation and productivity. As industries look to the future, embracing such transformative practices may well be the key to navigating the complexities of market demands, ensuring sustained success in an ever-evolving landscape.