Understanding the Role of Freeze Drying in Pharmaceutical Manufacturing

Also known as lyophilization, freeze drying is a key process in the production of very delicate drug products as it guarantees their stability, effectiveness and shelf life. This procedure is critical for storing biological vaccines, proteins and other substances that can get easily destroyed by excessive heat or water. In this article, we will look at the role of freeze drying in pharmaceutical manufacturing, the process technologies involved, and the important functions carried out by pharmaceutical equipment suppliers and freeze dryer manufacturers in offering advanced solutions to the industry.

What Is Freeze Drying and Why Is It Essential for Biotech Products?

This biomedical technique of freeze drying is done by first freezing the product and then applying a vacuum. This causes the ice to sublimate directly into vapor. Water is removed using a sophisticated preservation technique which ensures the structural integrity of the product. For example, vaccines, biologics, enzymes and proteins are all quite heat and moisture sensitive. Freezing drying takes water out without any exposure to heat, thus avoiding the breakdown of biological sensitive organisms.

For biotechnology, the most important consideration for product shipping and storage is shelf life. It is usually refrigeration, but for some biotechnology products, the storage conditions are more complex to maintain. Freeze Drying helps extend the shelf life and also allows for the eliminated use of the refrigerator where it is not feasible. The use of refrigerated vehicles and constant power supply increases the cost greatly and is generally not viable. Life supporting products such as vaccines can now be transported and stored at room temperature without loss of potency. The cost efficiency does not end there. Effort is no longer required to maintain the state of the product.

Another aspect that is improved with freeze drying is the ratio of water to surfactant. With extremely little water in the composition, microbial maintenance and chemical breakdown is guaranteed. To pharmaceutical products, that enhances credibility in their safety and effectiveness. Maintaining biological materials in their valid state makes freeze drying a revolutionary advancement for the pharmaceutical industry.

See also: Electric Valve Actuators: A Game Changer for Energy Efficiency

Commonly Used Commercial Equipment Suppliers for the Lyophilization Process

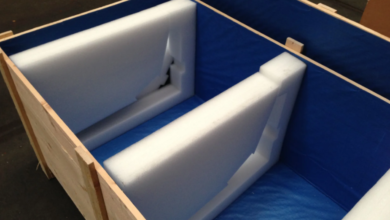

Freeze drying is a sensitive biotechnology process that involves removing moisture from biologically perishable materials like medicines, biotechnology products, food stuff and other materials. A specialized container is needed during the freeze dry process so that the already frozen product will be dry without going through the liquid state. These containers are manufactured by suppliers of Pharmaceutical equipment and they are the ones who hold the whole process together. These machines are required to be accurate and dependable for the preservation of important biotech products. Manufacturers never re Moines innovates the design and efficiency when it comes to freeze drying equipment since the Biotechnology industry will never stop growing.

The advanced features in freeze drying machines allow for control over very important parameters like temperature, pressure and humidity which are important in the process. The control on the machines has to be at the highest quality for most delicate biotech products. These machines are required to be precise and dependable, which is very important for solutions with biological activity such as enzymes and proteins.

Aside from improving freeze-drying machines, these manufacturers are focused on making them more energy-efficient and scalable. The global demand for products such as vaccines, biologics, and diagnostic tools is increasing, and so is the need for the biotechnology industry to be more efficient. It helps biotech companies lower their operational expenses, fulfill the growing demand for their high-quality products, and at the same time, ensure safety.

Pharmaceutical equipment suppliers are contributing significantly to the improvement of the freeze drying process by continuously innovating their products. These steps help biotech companies be sure that the preserved products that they are going to use by patients all over the world are well-protected and effective.

How Freeze Drying Changes The Game In The Storage Of Biotech Products

High-end freeze drying is a game changer in the field of biotechnology because it is a trusted method of ensuring the uniformity of certain fragile biological components. Vaccines, proteins, and other biologics require special measures to be stored, because they can quickly deteriorate when moist or overheated. Moisture can be removed without heat, ensuring that sensitive products remain in their structures and effective after being processed.

One of the most important beneficial features of freeze drying is its capacity to increase the longevity of biotech items by lessening the dependence on refrigeration to store them. Biotech items have, in the past, needed constant refrigeration in order to be useful which pose pardonable logistic and operational issues. However, freeze dried goods do not need to be refrigerated which means they can be stored at room temperature. This makes transportation easier and lessens the complications of supply chains, especially in remote areas or developing countries where refrigeration is not easily available.

Freeze drying, apart from its logistical advantages, aids in the reduction of wastage while making certain that biotech goods are useful for a longer time. Many biotech products, particularly vaccines and biologics, spend considerably large amounts of money to be produced, and any negative impact stemming from poor storage causes financial losses and, even worse, the deaths of people who require crucial life saving substances. These perils are alleviated greatly with freeze drying since it makes sure that products do not lose value throughout their lifecycle.

New Developments in Freeze Drying Technology

The technology used in freeze drying processes is gaining more support from pharmaceutical equipment suppliers and getting better in efficiency, speed and energy usage. The most important development of the recent past has to be the introduction of continuous freeze drying systems, which enables the product to be dried continuously instead of through separate batches. This enhancement increases throughput and efficiency of the freeze drying process, allowing a company to boost their production in order to satisfy demand.

Another leap forward for freeze-drying technology is the deployment of real time monitoring and control systems capable of offering data concerning temperature, pressure and humidity at all stages of the drying process. Such automation of the process enables freeze dryer companies to modify the produced parameters on every single temperature step’s outcome. Besides, the increased automation helps eliminate human errors, improving the consistency of the product.

Moreover, the newest freeze drying machines operate at lower energy levels, which also lowers the cost of using them, making them much cheaper to operate overall. These improvements are allowing companies to achieve the increasing demand for biotechnology products while still providing quality at reasonable costs.

Conclusion

In the field of pharmaceutical manufacturing, freeze-drying has significant importance since it guarantees the stability of sensitive products such as biologics, vaccines, and proteins on a long-term basis. The unique capability of removing moisture while maintaining the potency of these products has greatly altered their storage, transport, and distribution. Providers of pharmaceutical equipment, as well as manufacturers of freeze dryers, are at the forefront of developing modern advanced freeze drying systems that enhance the efficiency, scalability, and cost-effectiveness of these procedures.

With the continuous growth in demand of biotech products, the innovation of freeze-drying technologies remains crucial in maintaining optimum safety, efficacy, and accessibility to patients across the globe. There is no question that the future of preservation of biotech products looks very bright, due to the endless strides forward made by providers of pharmaceutical equipment and manufacturers of freeze-dryers.